Welcome to the Jetsons: How Robots Will Change Society

Our lives are heavily influenced by technology. With each new piece of technology that comes out, we are finding it easier and easier to manage our daily lives. One trend that I have been keeping my eye on is how robotics is evolving. We are on the precipice of an exciting time in history in which robots and other advanced forms of automation will be commonplace.

In this article, I will examine how robotics is already changing society and speculate about what changes may come in the next few years and what that means for business.

Overview and Current Advancements

Robots, by definition, are programmable machines that can carry out both simple and complex series of actions automatically. This flexibility and tireless devotion to the task at hand makes them a game changer in certain industries—especially those where manual labour is key.

It is easy to see why people are worried that robots will take over the world and make life more difficult. But this fear does not reflect how these machines have made our lives easier in the past—and it certainly will not affect their continued usefulness in the future.

Although it's difficult to declare any technology as the first, one robot, in particular, is widely accepted as the very first modern industrial robot: Unimate.

It was created to lift hot pieces of metal from die-casting machines and transport them to a different spot – a task that humans had previously done by hand. Due to the inherent danger of moving hot metal objects and the importance of this work, it made sense for an unfeeling machine rather than a human worker to perform these operations.

George Devol spent a decade attempting to build and operate such a robot; it was the late 1960s efforts of Joseph Engleberger, however—including his ability to obtain funding and attract interest among industry leaders in this innovation—that got robotics off the ground. For this reason, he is often called "the Father of Robotics."

Unimate demonstrated the potential of industrial robots. Computer scientists, however, believed that robotics could be used for far more than just moving hot objects around a factory floor.

Shakey the Robot, created by SRI International from 1966 to 1970, was a groundbreaking achievement: It was the first robot capable of performing tasks independently without human instruction. Shakey helped develop techniques that are now used in artificial intelligence programs. These include visual analysis (for example, seeing what's around you at any given time), route finding ("How do I get to where I want to go?"), and object manipulation, to name a few.

In 1970, researchers at Waseda University in Japan developed the first full-scale anthropomorphic robot. Although it may seem inferior compared to other robots currently on the market, WABOT-1 represented an enormous leap forward in humanity's understanding of androids. This machine is seen as a step toward what many people consider the future: personal robots that can perform all sorts of tasks.

Building on this, the scientists who created WABOT-1 wanted to develop a robot capable of creative endeavours. In 1980, WABOT-2 was unveiled—a musical prodigy capable of playing the keys on an electric organ, reading sheet music, and talking with someone to accompany someone singing.

This machine has been considered an essential step in creating personal robots.

Fast forward, the P2 robot created by Honda was the first two-legged humanoid. Weighing 210 kilograms (462 pounds) and standing one meter eighty-two centimetres tall (5'9"), the machine was roughly human-sized.

One of the significant advancements of the P2 system was that it ran on a battery and had a wireless radio connection. This allowed users to make commands with greater freedom than they would have with other robots. This robotic machine could perform many of the same tasks a human would be able to do, such as walking at 2 km/h (1.24 mph) and pushing a cart upstairs.

Since the arrival of the new millennium, advances in robotics have spanned many fields and industries. A Canadian robotic arm was launched in 2001 and attached to the International Space Station. The Canadarm 2, as it is called, plays a crucial role in maintaining the station—one that no other machine has ever been able to do before.

In addition, the unmanned aerial vehicle Global Hawk made a 22-hour nonstop flight in 2001, from California across the Pacific Ocean and Eurasia to land in Edinburgh, Scotland—setting an endurance record for a robotic aircraft.

Later in 2017, Sophia, a robot created by Hanson Robotics and granted Saudi Arabian citizenship, is now the first to be recognized with gender identity and nationality. The news has raised many ethical concerns about how such developments in artificial intelligence might one day impact human rights issues—such as whether murder laws would apply if Sophia were turned off. In my personal experience being in contact with Sophia in 2017, I could realize that its development is a foretaste of what the future will look like when we are surrounded by robots, although it definitely still requires many technological advances to reach this point.

The Impact of the Pandemic

More recently, when the coronavirus crisis took hold in early 2020, many roboticists saw an opportunity: robots could be programmed to work with minimal supervision and continue working even when their human coworkers fell ill.

In a 2020 report, Robotics & COVID-19: How Robotic Technologies are Critical in Getting America Up and Running in The Age of the COVID-19 Pandemic, created by The American Society of Mechanical Engineers (ASME), experts argued that the crisis should be used to supercharge medical robot development: Robots never get sick and can do dull, dangerous work that puts human workers at risk. Robots could administer medicine and take patients' vitals, freeing up doctors and nurses to do what they do best: interact with patients on a human level.

The British company, Engineered Arts, unveiled Ameca at the Consumer Electronics Show in January 2022, making headlines worldwide. Ameca is a humanoid robot that has movable arms and a hyper-realistic face, making it "the perfect humanoid robot platform with which to interact in human-like ways", according to its creators. In addition, Ameca's creators say they created a user-friendly platform for testing artificial intelligence and machine learning, making it ideal for developing human/computer interaction in any digital realm.

Replacing humans with robots might not always be the best choice—some jobs require a personal touch. Although there is widespread recognition that we have created a new species of intelligent machines, how we will respond when confronted with the consequences of what we have done remains to be seen.

Robots Will Create Jobs, Not Destroy Them

The World Economic Forum projected in 2020 that by 2025, technology would create at least 96 million jobs more than it destroys—a sign that automation will likely be a net positive for society in the long run.

The concern over machines replacing humans in the workplace has been a topic of discussion since the Industrial Revolution and continues to be so as automation becomes increasingly widespread. While there has been much hype about how automation—particularly robots, which do not need humans to operate them—would affect employment and wages, less attention has been paid to evidence-based research on the subject.

According to Acemoglu and Restrepo, workers often experience adverse effects, such as losing their jobs or being forced to take lower-paying positions in other industries, when automation technologies replace them.

Acemoglu and Restrepo argue that robots are likely to take jobs from workers in routine manual occupations—such as machinists, assemblers, material handlers, or welders.

According to the same study, both men and women are affected by adopting robots, though men are more likely to be displaced than women. For men, impacts were seen most in manufacturing jobs—where automation has been readily adopted. For non-manufacturing jobs, it is a different story: for both genders in these fields impacted by technological advances (such as radiology or policy writing), the effects on employment have proved mixed.

The researchers found that the adoption of industrial robots does not seem to improve the employment situation of workers with advanced degrees, which could indicate that, unlike other forms of technology, robotics does little to directly augment the work performed by high-skill labourers. Overall, the impact of robots is mixed. While they replace many jobs formerly performed by relatively low-paid workers, they also make firms more efficient and productive than ever before.

In the wake of the COVID-19 pandemic, Acemoglu noted that economic crises tend to exacerbate both positive and negative implications brought about by technology. Without the use of advanced digital technologies like Zoom or other software, it would be impossible for people to teach and teleconference in various locations around the world. Factories would not be able to keep running—as many have not fully recovered from these circumstances but are slowly getting back up on their feet—if workers could not work remotely using these same types of advances.

Mark Lewandowski, P&G's director of robotics innovation, said that some of these events may accelerate because there are potential business interruptions that you need to be prepared for, and COVID-19 just highlighted these issues.

More than ever, companies are re-examining their production processes and looking for ways to keep costs down even as labour shortages or trade disputes drive up the price of key inputs. This has encouraged the acquisition of robots to automate workflows on an ongoing basis. According to predictions made in 2020 by the World Economic Forum, automation and new divisions of labour between humans and machines will disrupt 85 million jobs globally in medium-to-large businesses across 15 industries by 2025.

How Robots Can Deliver Real World Benefits Now

Today, robots are most commonly associated with a variety of situations involving military or commercial aircraft and vehicles. But the time has come when we must expand our concept of robots beyond those of a mechanical nature. Here is how robots are poised to be that extra support we all need now and then.

Teams freed from the work of implementing business processes will be able to focus on higher-level activities

I have written in the past that robots can free humans from performing basic, low-level tasks—not by replacing us at work but by doing those mundane jobs, so we don't have to.

A study titled The Augmented Human Enterprise, conducted by the University of London and sponsored by robotic automation company Automation Anywhere, found that organizations augmented with automation technologies are 33% more likely to be "human-friendly" workplaces.

AI can perform routine work such as updating employee payroll lists and transferring data from files.

Robotic Process Automation (RPA) is a technology that automates unswerving tasks, such as those performed by bookkeepers and customer service representatives. Employees who no longer have to perform simple, repetitive tasks can now focus on more challenging and creative work that will benefit the company.

Robots can perform tasks that humans do not want to take on

Labour shortages in agriculture are common worldwide, and farmers have trouble hiring enough people to plant or reap their crops.

In response to this demand, some farms are using robots to eliminate the need for human workers—that is, they are using them to perform simple but tedious tasks like picking berries, packaging salads, and weeding fields.

In the United States, there is 52% of reported labour shortages on farms, and produce is often wasted due to underuse or lack of knowledge about preservation methods; new farming technologies are necessary for ensuring that crops are not lost, and robots could be the answer.

They make goods or services that were once out of reach more accessible

There is no debate that robots are more efficient at manufacturing goods than humans. Robots can work with greater accuracy, which reduces wasted materials and labour—and they can keep going when human workers need rest.

Lower manufacturing costs have made goods cheaper, making them more accessible to a larger number of people—regardless of their income level or employment status. The cost of a latte could decrease, for example, if coffee shops rely less on labour and more on automated machines to make the coffee. Check out this incredible robotic coffee bar, CafeX, located in San Francisco and Dubai, with great customer reviews.

For another example of the value of AI, a translation device allows people to travel anywhere and interact with other cultures as they please. However, rather than being confined by typical tourist routes or language barriers.

This is the case of the Greek National Technology and Research Foundation when created Persephone, a polyglot tourist guide robot that can speak 33 languages with visitors of the Alistrati Cave.

They will improve work-life balance

As mentioned in the first statement: people will have more leisure time available to them once robots can perform at least some of their daily job functions. There is also a question about whether adequate measures can be implemented to help workers who lose their jobs because of automation and whether employers will continue to recognize human employees' value.

Rather than seeing robots as a threat to workers, imagining the benefits they will bring is more fruitful. The impact of this new technology will be incredibly transformative as it will give people access to goods and services that have only been available to the wealthy, thereby increasing their quality of life and helping them find work they enjoy more.

What Industries Will Be Most Impacted By Robotics Advancements?

Robotic advancements will profoundly impact many industries. These include healthcare, education, manufacturing, and other industries that require a lot of manual labour. We are witnessing how robots created with the latest developments in AI have been able to automate complex human jobs in these industries and will continue to do so in the next few years.

In some cases, they are helping to overcome physical limitations by scientific development in the medical field or assisting humans with dangerous tasks (or simply doing them for us). The advancements in robotics technology will most likely impact the following industries.

Healthcare

Robotic technologies are being developed for many areas of patient care. In the hospital, they can be used to disinfect rooms and operating suites, reducing the risk that infectious diseases will spread among patients and medical personnel; in laboratories, they work to process samples—taking them from wherever they were collected and moving them through different stages of testing.

A great example is the Xenex-Germ Zapping Solutions created to eliminate pathogens missed during manual cleaning and assist infection control programs' efforts to reduce environmental contamination. Its primary customers are top hospitals in the U.S.

It is particularly good news for anyone who has ever had blood drawn by someone whose stick-to-itiveness was less than legendary—the robotic lab assistant can find the vein and draw blood with minimal discomfort.

In some facilities, robots deliver linens and meals to patients' rooms. In others, they prepare medications in the lab on their own and carry them—as well as food trays with patient-ready plates of food—from floor to floor through automatic doors without human intervention. In addition to robotic walkers, some mechanical assistants help paraplegics move—and can administer physical therapy.

Such is the case of ReWalk. The ReWalk exoskeleton is a wearable robotic device that provides powered hip and knee motion to enable individuals with spinal cord injury or disease (SCI/d) to stand upright, walk, and turn around corners—in essence, it allows them to regain their mobility. ReWalk is the world's first FDA-approved exoskeleton.

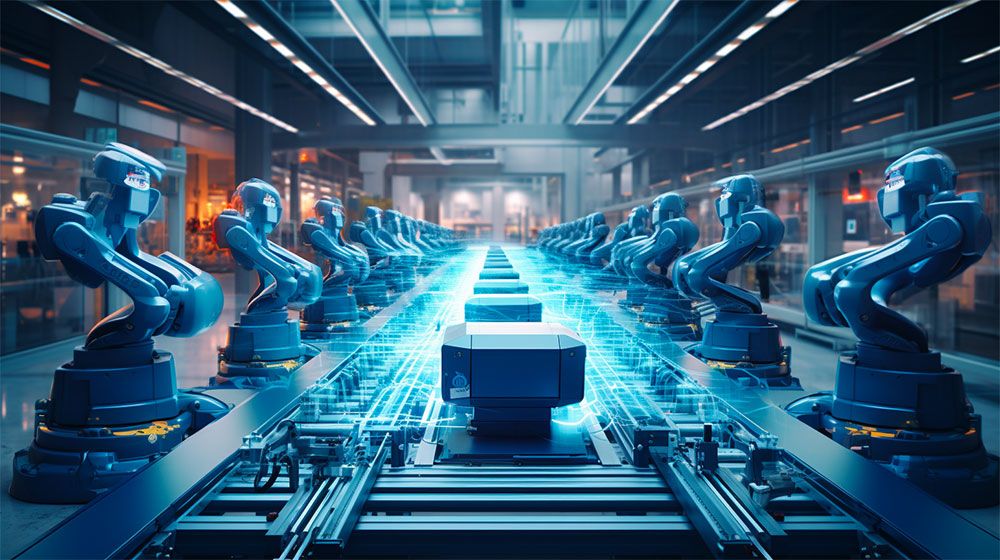

Manufacturing and Logistics

As a result of increasing demand for efficiency and cost-savings, logistics robots are an increasingly common sight in today's warehouses. To meet the ever-increasing demands for efficient and agile operations, companies have invested in automating movements as well as different areas within their facilities with automated storage and retrieval systems (AS/RS).

As part of their strategy for improved competitiveness, companies are increasingly turning to logistics robots. In a conventional warehouse, humans often do order picking, making it more expensive to operate around the clock. Logistics robots ensure that goods can flow quickly through an industrial plant or distribution centre—allowing for round-the-clock operations and maximum protection of people, merchandise, and other assets involved in the transaction.

Depending on the job, robots may perform one of many tasks.

- Goods receipts and shipments can be carried out by logistics robots, like automatic truck loading and unloading systems, which makes it possible to insert/remove pallets from trucks autonomously with minimal operator intervention. Automated conveyor systems can be used to speed up goods receipt and dispatch, two key warehouse processes with the highest number of daily movements.

- Storage robots are a type of industrial robot designed to move products from one location or bin to another. Stackers, for example, have been built to store boxes and pallets on racks at distribution centres by moving them from station to station until they're shipped out again.

Stacker cranes come in three main varieties: single-mast, twin-mast, and trilateral. These logistics robots travel horizontally along storage aisles to lift pallets out of or lower them onto the racks as needed—all without any human intervention required. Businesses with high volumes of goods entering and leaving the facility can also utilize an automated storage solution called a pallet shuttle. Electric shuttles glide through channels to expedite loading and unloading processes with this system. - Order picking is one-way logistics robots can be used in order preparation. A single storage solution may include both a stacker crane for boxes and a conveyor for boxes. In this configuration, the operators remain at their pick stations preparing orders according to the goods-to-person method: an order is filled when it reaches its destination—the customer's box or hand.

Industrial robotic arms can perform pick and place—removing products from one location, organizing them in another—to streamline the picking process. - Warehouse robots. Box and pallet conveyor systems are one of the most effective solutions for facilitating internal goods movements in a warehouse because they make it possible to build varied configurations connecting various zones within the facility.

Warehouses may use electrified monorails to link different areas. An electric motor drives these automatic trolleys, and they move along rails suspended from the ceiling or fixed at floor level.

Finally, companies turn to automatic guided vehicles (AGVs) or autonomous mobile robots (AMRs) to transport goods between departments.

- Drones have taken over the logistics industry. Their technology enables them to transport and deliver customer orders by air — a method of delivery that has not been used before, but now there are many companies taking advantage of drone technologies like Amazon, which is focusing on delivering their products via drones directly home deliveries with no human involvement at all.

The use of drones would produce several benefits, including lower costs, faster delivery times (compared to conventional shipping methods), less congestion on the nation's highways—and, therefore, a significant reduction in pollution.

Delivery by drone has great potential in densely populated areas. However, it could also be useful for delivering medicines or supplies to people living in rural communities and isolated villages.

To keep up with the rapid expansion of high-tech businesses in Silicon Valley, RK Logistics recently expanded its site in Livermore by 300,000 square feet. The facility now handles considerably more volume than before. But RK Logistics' clients were demanding more throughput, and the company's facility was nearing its capacity limits.

To increase the productivity of its workers and improve the throughput of its facilities, RK Logistics evaluated the use of robotics. The company decided to use Fetch Robotics' VirtualConveyor solution.

The VirtualConveyor solution integrates Freight series robots, charging stations, and the Fetchcore fleet management system. By combining these components into a single cohesive whole—rather than operating them independently—the entire process has become more efficient and is better able to handle fluctuations in demand, representing a successful case study within the logistics industry.

Foodservice and consumer goods

While COVID may have accelerated the push for contactless food prep and service, it is part of a larger trend that has been in place for some time. Food service companies that combine food robots and full-service automation platforms will be able to minimize unnecessary contact between workers and the food, ensuring both its safety for consumers (and the health of employees).

Robot-assisted solutions help food managers ensure that a broad range of safety protocols are met, ensuring that high standards for quality and customer satisfaction are maintained.

Robotic systems can automatically perform functions such as cleaning, timing, and monitoring important aspects of the food storage/preparation process and eliminate cross-contamination risks while optimizing food quality and shelf-life. Robots can be deployed to better monitor food safety and logistics around the clock, a feat that would otherwise prove difficult given staffing limitations at most restaurants.

During the pandemic, countless entry-level food service workers moved on to other positions. According to the U.S. Bureau of Labor Statistics, over the next decade, about 45,000 jobs for food service managers are projected each year. Many of these openings will result from workers transferring to different occupations or exiting the labour force (such as retiring).

Unstaffed positions are slowing economic recovery for food services managers who depend upon these employees to keep their establishments flourishing during hard times.

Robots can help restaurant owners add consistency to their food service and reduce the headaches of finding, hiring, training, and retaining human staff.

Food automation platforms are the future of fast food, using robots to deliver on the promise of personalized, healthy, fresh, and delicious food while reducing overhead costs—all with a push of a button.

Food automation solutions digitize the ordering process, allowing customers to use their smartphones or tablets at an eatery to easily choose items, make customizations, and schedule delivery times. The robotic kiosks should be able to prepare the customer's order and store it safely until they arrive at the kiosk to pick it up.

An example of robots used in the food service industry includes Picnic. This robot's pizza-making process can be automated using this modular, customizable system. First, spread the sauce on a sheet of dough; then top it with cheese and pepperoni. Add your three favourite ingredients, bake—and you're done!

Picnic can produce hundreds of pizzas per hour, which allows the rest of the staff time to focus on other food items.

Another excellent example of food automation is Flippy. This robot is a hamburger-cooking machine that replaces human labour in restaurant kitchens. Last year, Miso Robotics, the company that created this robot, announced Flippy 2, a new version of its hamburger-cooking robotic arm. The upgrade is designed to further automate simple cooking tasks for fast food establishments.

Finally, Cecilia.ai is a smart, interactive bartender that can be placed almost anywhere—from home to busy bars and restaurants. It serves mixed drinks in less than 30 seconds and gives customers guidance about menu options using AI/speech recognition technology. It can be easily installed in hotels, casinos, and cruise ships as the primary or backup bartender.

Automotive

Automotive assembly lines are subject to a variety of problems, including worker injuries, slow production times, and defective products. Using robots can help solve these problems.

Ford uses UR10 cobots in Romania to grease camshafts, fill engines with oil and perform quality inspections. Ford's Romanian factory has sped up its process, freed employees from repetitive tasks, and improved product quality by deploying these cobots.

Robots can be programmed to perform almost any physical task involved in vehicle construction. There are many ways that robots can assist in making decisions. For example, robots may perform quality inspections on the final product—pass/fail style—to ensure it meets a certain standard of quality before being shipped off for sale.

The automotive industry relies on a variety of workers to complete essential tasks: assembly, painting, welding (including robots), material removal, and polishing.

Between 2017 and 2019, Tesla was near bankruptcy. The company had invested billions of dollars in a new factory filled with robots—but the machines couldn't meet production quotas and often didn't work correctly. Today, Tesla is one of the world's most valuable companies in the automotive industry. Its automated production process has allowed it to leap ahead of competitors.

Although humans are involved in manufacturing, most processes require little or no human intervention. Tesla uses over 1,000 robots. Some robots on the manufacturing floor are big enough to lift an entire car, while others are small enough only to pick up smaller objects. Some have complex programming, and some rely on simple instructions or proximity sensors to guide their actions.

The large-scale use of automated systems within Tesla's factories helps reduce costs and improve the speed with which goods are moved around. As you can see, Tesla's goal is to rely on automation in its manufacturing process as much as possible.

To address production problems, other automobile manufacturers rely primarily on robots for heavy lifting or extremely fast processes. Tesla's goal is to use the most state-of-the-art robotics and other technologies it can get its hands on—in innovative ways that are both efficient and cost-effective.

Robots do not replace humans in the auto industry. In many sectors, like final touches and quality control, human workers are needed to perform tasks that robots cannot yet accomplish. When robotic precision is coupled with human creativity and flexibility—as it inevitably must be if advances in automotive technology are to continue—both fields will benefit from a creative synergy between man-made machinery and biological lifeforms that no one before us had ever been able to imagine or create in a roundabout way.

The Good and Bad of Robotics Developments

The expansion of the artificial intelligence and robotics industry is one significant factor that impacts and transforms various aspects of everyday life—a transformation fostered by rapid technological change.

Personal service robots, engineered to help people with everyday tasks, have become more common. For example, the robot assistant named Alexa in many homes and the nurse-assistive robots used by hospitals worldwide.

It is predicted that these service robots will become more integrated into people's everyday lives—transforming sectors such as agriculture, logistics, and retail in particular. As a result of their increased presence, businesses must adapt their operations to changes in social constructs.

As robots become more intelligent and pervasive in industry and society, they will help solve some of humanity's greatest challenges. At the same time, new job opportunities—hundreds of new professions—will be created by these advances.

However, each coin has two sides, and so do robots. While they have many advantages—such as the ability to perform repetitive tasks with precision—they can also have major drawbacks, such as being able to replace humans in certain jobs, which would leave those people unemployed.

Robots have two major downsides. First, they replace humans in the workforce, increasing unemployment rates. Second, robots are very expensive to produce and use (depending on your point of view). Robots are made after extensive research and development, which requires high technology with extensive investments that most people do not have. In essence, robots can be expensive to purchase, maintain or rent. Their high price tags raise the cost of manufacturing goods and merchandise.

Although robots are manufactured and used primarily for production purposes in an organization, they often increase the costs of production due to their expensive nature. At the same time, however, they reduce overall costs by replacing human labour. While they reduce costs due to lower levels of wastage, the initial investment is still high.

Additionally, operating robots requires specific expertise from the employee to program and interact with them. This is also one of the disadvantages of robots, as they cannot perform many scientific tasks independently and thus require considerable human interaction.

We are witnessing a revolutionary transformation in how people, businesses and societies interact. In the long run, it may turn out that we underestimated both the positive and negative effects of this disruption. However, we need to start preparing for them as soon as possible.

Governments and C-Level executives should create a working environment that will enable everyone to benefit from the shifts brought about by innovation. This includes education and training for human workers, support for research activities—and investment in innovations.

Final Thoughts

Technological advances move at an ever-increasing pace, and there is no sign of slowing down. How we interact with technology is shifting, as well as how intrinsically we rely on it. From our iPhones to being greeted by customer service chatbots, our lives are being shaped and changed by the machines that man was initially meant to control. There is still a long way to go before robots become a part of our everyday lives.

As the Jetsons so aptly illustrated in the 20th century, robots may not be a typical sight in society today. However, the trend toward automation and technology will only continue to grow more widespread, transforming our traditional means of doing work into entirely new systems.

Image: Hanna-Barbera Productions